In A Business What Is Production Of Services Responsible For?

Achieving World-Class Operations Management

82 Production and Operations Direction—An Overview

- Why is product and operations management important in both manufacturing and service firms?

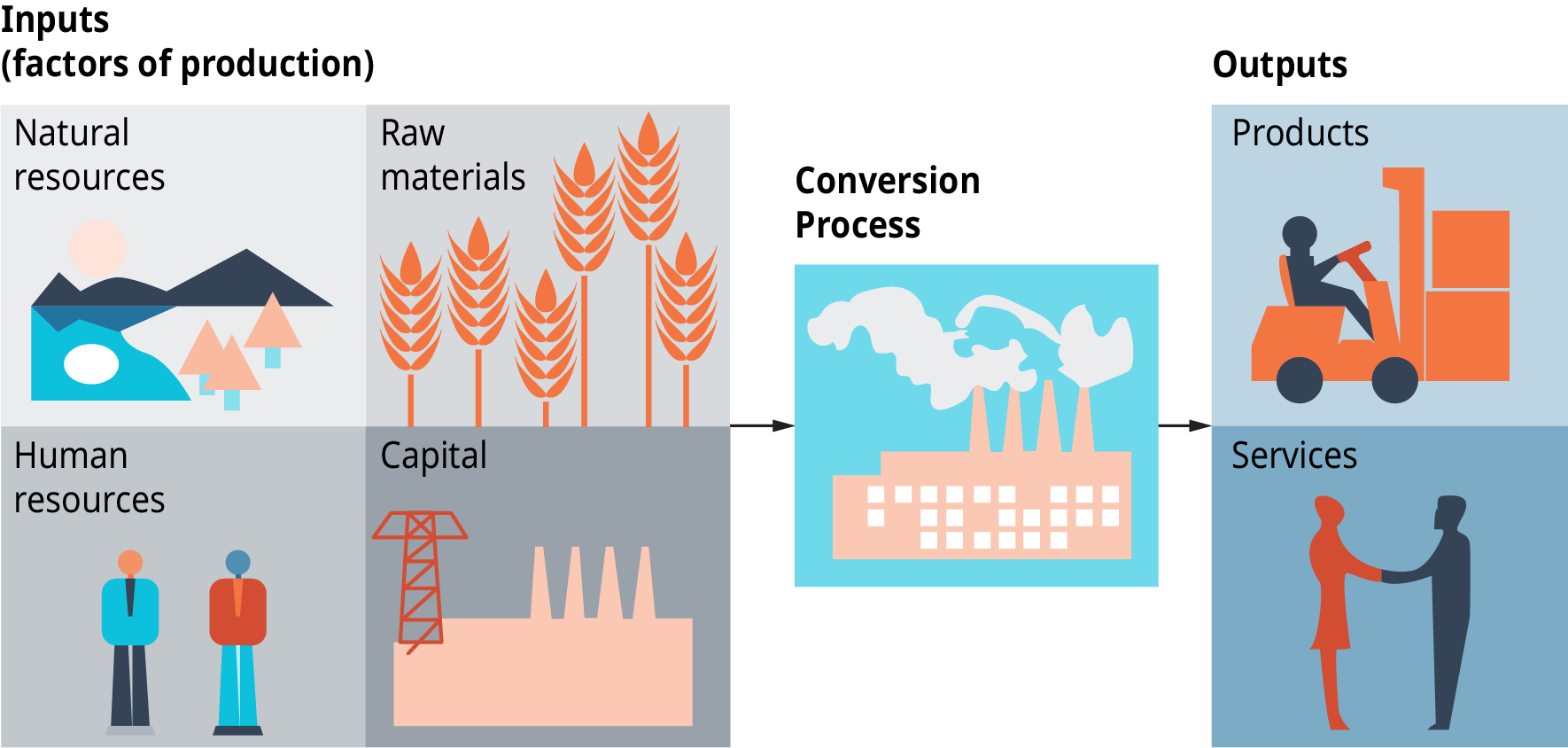

Production, the creation of products and services, is an essential part in every firm. Production turns inputs, such every bit natural resources, raw materials, human resources, and capital, into outputs, which are products and services. This process is shown in (Figure). Managing this conversion process is the function of operations management.

With new oil reserves at present available through "fracking," the United States is challenging Saudi arabia and is set to go a vast supplier of oil worldwide. Unlike the polish petroleum that gushes from Arabian wells, all the same, America'south black golden in the Marcellus, Bakken, and other shale regions has to be drilled horizontally through new technology. The process is rigorous: oil and gas companies drill into the footing to extract rough oil and natural gas from the shale stone that lies thousands of feet under the ground. Once the formation is reached, gallons of water, sand, and an extensive list of man-made chemicals are injected into the well under high pressure. This combination inserted in the well will fracture the rock and release crude oil and natural gas. It is estimated that the gas within these stone formations could supply the United States for generations to come as technologies evolve to drill beneath the world's surface. What are fundamental inputs in the fracking process? (Credit: Marker Dixon/ Flickr/ Attribution ii.0 Generic (CC BY 2.0))

The goal of customer satisfaction is an important function of constructive production and operations. In the past, the manufacturing function in most companies was inwardly focused. Manufacturing had little contact with customers and didn't always understand their needs and desires. In the 1980s, many U.S. industries, such as automotive, steel, and electronics, lost customers to strange competitors because their production systems could not provide the quality customers demanded. As a result, today most American companies, both large and small, consider a focus on quality to be a central component of constructive operations direction.

Production Process for Products and Services

(Attribution: Copyright Rice University, OpenStax, nether CC BY 4.0 license.)

Stronger links betwixt marketing and manufacturing also encourage production managers to exist more than outwardly focused and to consider decisions in lite of their effect on customer satisfaction. Service companies find that making operating decisions with customer satisfaction in heed tin can exist a competitive advantage.

Operations managers, the people charged with managing and supervising the conversion process, play a vital part in today's firm. They control well-nigh three-fourths of a firm's avails, including inventories, wages, and benefits. They also work closely with other major divisions of the firm, such equally marketing, finance, bookkeeping, and homo resources, to ensure that the firm produces its goods profitably and satisfies its customers. Marketing personnel help them decide which products to make or which services to offering. Bookkeeping and human resources assistance them face the challenge of combining people and resources to produce high-quality goods on time and at reasonable cost. They are involved in the development and pattern of appurtenances and determine what product processes will exist almost effective.

Product and operations management involve three main types of decisions, typically fabricated at iii dissimilar stages:

- Production planning. The starting time decisions facing operations managers come at the planning stage. At this phase, managers determine where, when, and how product will occur. They determine site locations and obtain the necessary resource.

- Production command. At this stage, the determination-making process focuses on controlling quality and costs, scheduling, and the bodily twenty-four hours-to-day operations of running a factory or service facility.

- Improving production and operations. The final stage of operations management focuses on developing more than efficient methods of producing the business firm'southward goods or services.

All three decisions are ongoing and may occur simultaneously. In the following sections, we will take a closer look at the decisions and considerations firms face up in each stage of product and operations management.

Gearing Up: Production Planning

An important function of operations management is production planning. Product planning allows the house to consider the competitive surroundings and its own strategic goals to find the all-time production methods. Practiced production planning has to remainder goals that may conflict, such as providing loftier-quality service while keeping operating costs low, or keeping profits high while maintaining acceptable inventories of finished products. Sometimes accomplishing all these goals is difficult.

From its storied creation in post-war Italy to its big-screen immortalization in movies such as Roman Holiday and Quadrophenia, the Vespa scooter has a reputation for romance, rebellion, and style. Manufactured by Italy'south Piaggio Group, the Vespa's graceful, stainless-steel chassis and aeronautic-inspired designs are seen everywhere in Europe and more and more in the United States. The Piaggio Grouping presently operates factories in Italy, Vietnam, India, and Cathay. What important product-planning decisions does Piaggio need to make as it considers expanding into more overseas markets? (Credit: Steve Watkins/ Flickr/ Attribution-2.0 Generic (CC BY2.0))

Production planning involves iii phases. Long-term planning has a time frame of three to five years. Information technology focuses on which goods to produce, how many to produce, and where they should be produced. Medium-term planning decisions encompass about two years. They concern the layout of factory or service facilities, where and how to obtain the resources needed for production, and labor issues. Short-term planning, within a i-year time frame, converts these broader goals into specific product plans and materials management strategies.

Four important decisions must exist made in product planning. They involve the type of production process that volition be used, site choice, facility layout, and resource planning.

- What are the three types of decisions that must be made in production planning?

- What are the three phases of production planning?

Summary of Learning Outcomes

- Why is production and operations management important in both manufacturing and service firms?

In the 1980s, many U.S. manufacturers lost customers to strange competitors considering their production and operations management systems did not support the loftier-quality, reasonably priced products consumers demanded. Service organizations also rely on effective operations direction in order to satisfy consumers. Operations managers, the personnel charged with managing and supervising the conversion of inputs into outputs, work closely with other functions in organizations to assist ensure quality, customer satisfaction, and fiscal success.

Glossary

- operations management

- Management of the production process.

- product

- The creation of products and services by turning inputs, such as natural resources, raw materials, human resources, and upper-case letter, into outputs, which are products and services.

- production planning

- The aspect of operations management in which the firm considers the competitive environment and its own strategic goals in an effort to detect the best product methods.

In A Business What Is Production Of Services Responsible For?,

Source: https://opentextbc.ca/businessopenstax/chapter/production-and-operations-management-an-overview/

Posted by: benderemenim.blogspot.com

0 Response to "In A Business What Is Production Of Services Responsible For?"

Post a Comment