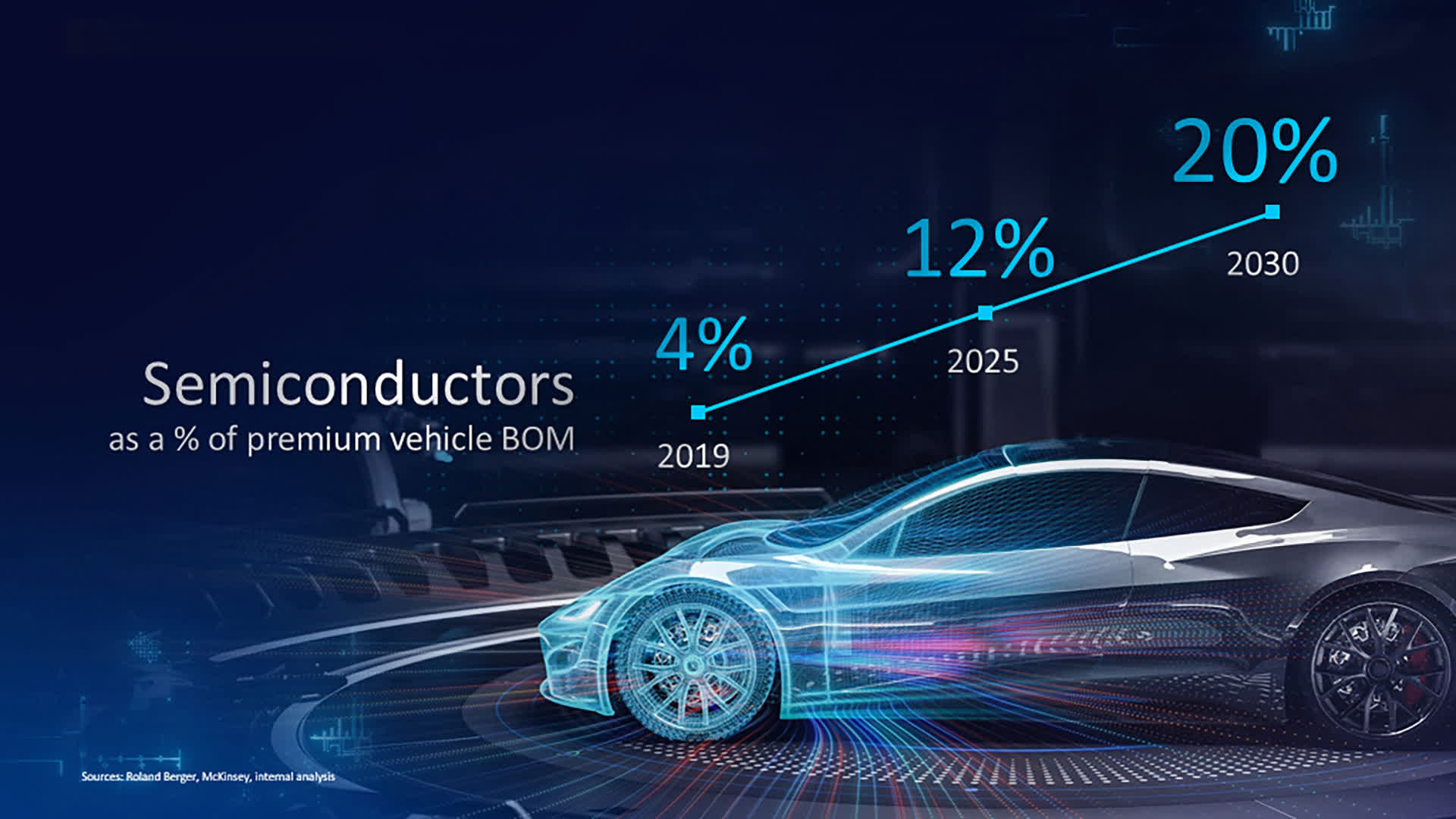

Intel CEO believes over 20 percent of premium vehicles' bill of materials will be dedicated to chips by 2030

In brief: With the modernization of vehicles, the number of fries needed to industry them increased proportionally. By 2022, semiconductors but deemed for four pct of a premium vehicle'southward neb of materials (BOM), but this value is expected to grow in the coming years. By 2025, 12 percent of the BOM should be used on chips, growing to 20 percentage by 2030.

The predictions presented at IAA Mobility by Pat Gelsinger, Intel'south CEO, represent 5x growth over eleven years. Likewise the increase of semiconductors to manufacture premium vehicles, Gelsinger besides expects to see the total addressable marketplace (TAM) hike to $115 billion by the cease of this decade, representing over 11 per centum of the unabridged silicon TAM by and so.

Co-ordinate to Gelsinger, the reason for this is "the digitization of everything" aslope the other "four superpowers:" ubiquitous computing, pervasive connectivity, cloud-to-border infrastructure, and AI. These 4 are paving their mode into the automotive industry, equally manufacturers offer driverless systems, driving assists, navigation systems, improved security features, so on.

The increased demand for semiconductors is prompting Intel to invest in new fabs and upgrade existing ones. In the U.s.a., we already know near Intel'due south plans of a $120 billion mega-fab and the $three.five billion investment in the New United mexican states fab. Beyond the pond, the company plans to build 2 fabs with a joint investment of €80 billion.

Intel is besides discussing with its European partners the best style for them to use improved node processes. Vehicle fries are predominantly based on older nodes, but Intel expects to modify this in the coming years. To do then, the company is committing capacity in its Ireland fab to the automotive industry, besides every bit launching the Intel Foundry Services Accelerator, a program designed to help automotive chip designers transition to advanced nodes.

"This new era of sustained demand for semiconductors needs bold, big thinking," said Gelsinger. "As CEO of Intel, I have the great privilege to exist in a position to marshal the energies of 116,000 employees and a massive chip-design and manufacturing ecosystem, to meet the demand."

Gelsinger'due south expectations come among what might be the worst time of the ongoing chip shortage, equally chip lead times recently reached record highs of 26.5 weeks and foundries increased bit prices significantly. Fifty-fifty car manufacturers like Toyota had to cutting production by 40 per centum because of the ongoing state of affairs.

We sincerely promise Gelsinger'southward expectations tin be met and meliorate the dire status in which the semiconductor industry is currently in.

Source: https://www.techspot.com/news/91152-intel-ceo-believes-over-20-percent-premium-vehicles.html

Posted by: benderemenim.blogspot.com

0 Response to "Intel CEO believes over 20 percent of premium vehicles' bill of materials will be dedicated to chips by 2030"

Post a Comment